DRY ICE RESTORATIONS

ABOUT US

Who we are

Dry Ice restorations operate from a bespoke dry ice car cleaning facility in Aradippou Larnaca. We are fully insured, have on-site security with CCTV and monitored intruder alarm for piece of mind.

Born from a lifelong passion for motor cars, Dry Ice restorations was set up to offer the best cleaning and restoration service available anywhere. We are passionate about restoring and preserving cars.

We have made a significant investment in the latest dry ice cleaning technology ensuring the very best results for our customers. The machine we use allows us to precisely adjust the cleaning strength giving the best possible clean in the safest way.

A special thanks to our partners

We are Cyprus's first qualified Dry Ice blasting service

The Technology

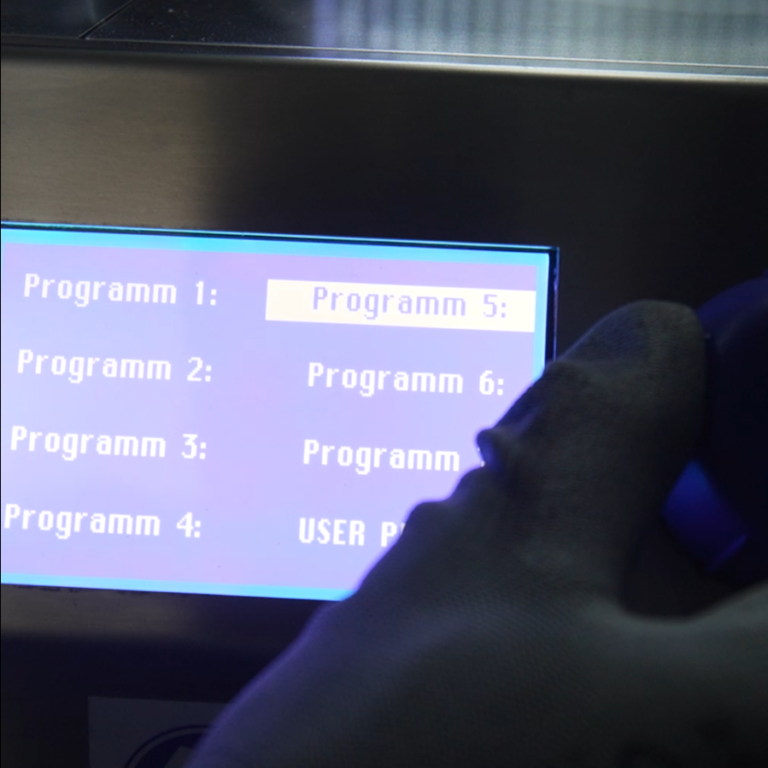

We use the best dry ice blasting technology on the market. It’s the only one that allows “on the fly” CO2 particle size adjustment during blasting. This unique feature means we can adjust the cleaning intensity to suit any surface and any contaminant in a safe way.

Whether we’re gently cleaning delicate Ferrari crinkle cam cover paint or blasting off underseal from a classic car underbody, we have the experience and technology to do so in a way that’s sympathetic to the car.

How it works

Soft CO2 particles are blasted at high pressure onto the surface to be cleaned. The low temperature of the CO2 (-79 degrees C) reduces the contaminant’s adhesion through thermal shock . Upon impact the CO2 immediately expands back to a gas (sublimates) causing mini explosions that lift the contaminant off the surface.

The process is safe on delicate paint and is also better for the environment than conventional methods.

Coolmaster Technology

CoolMaster starts where others reach their limits

Unbeatable for flexibility and range of application, CoolMaster is perfect for removing contaminants in all sectors. Particles of various sizes, surfaces and degrees of soiling are cleaned efficiently and powerfully, yet gentle to the material saving resources and being less time consuming than traditional cleaning methods.

CoolMaster reduces the downtime of machines, as they often do not need to be dismantled, and can be cleaned right in place.